T4K3.news

New metal alloy production method announced

Caltech scientists reveal a groundbreaking technique for creating versatile metal alloys.

Caltech researchers unveil a groundbreaking technique for creating metal alloys with enhanced properties.

Breakthrough method transforms metal production for modern needs

Scientists from Caltech have introduced a revolutionary method for producing metallic objects with precise shapes and specific chemical compositions. This method offers unprecedented control over the alloys created, which could lead to advancements in fields such as medicine and aerospace. The technique, known as hydrogel-infusion additive manufacturing (HIAM), allows for the combination of metals in ways that traditional methods cannot achieve. By merging copper and nickel, they can design materials that are both lightweight and durable, suitable for applications like biocompatible stents and robust satellite components.

Key Takeaways

"You can actually fine-tune the chemical composition and the microstructure of metallic materials."

Julia R. Greer emphasizes the level of precision the new method offers in alloy production.

"One of our colleagues described this work as bringing metallurgy into the 21st century."

Greer shares the ambitious perspective of the impact this technique could have on the field.

The introduction of this new technique marks a significant shift in metallurgy. Traditional methods often limit the mechanical properties of metals due to their reliance on raw materials and time-consuming refinements. This innovation could lead to more efficient production processes, ultimately transforming how industries approach metal design. As the researchers noted, this advancement could not only enhance the performance of everyday products but also push the boundaries of engineering capabilities in extreme environments, such as outer space.

Highlights

- This method allows for the alloys to be designed in ways previously thought impossible.

- Hydrogel infusion brings metallurgy into the modern age, impacting multiple industries.

- Creating metal with exact specifications could lead to stronger, more efficient materials.

- These alloys could redefine what is possible in aerospace and medical technology.

Potential impacts on industry standards

The new method could disrupt traditional metallurgy practices, leading to industry-wide shifts in manufacturing and design.

This innovation may redefine manufacturing strategies in diverse industries.

Enjoyed this? Let your friends know!

Related News

Silicon Valley start-up claims nuclear fusion can create gold

Lazenby Group announces expansion and job creation

Jenna Ortega shares details about Wednesday season 2

MP Materials signs $500 million deal with Apple

Google reveals AI advancements at I/O 2025

Disappointment in SpongeBob SquarePants Magic Cards

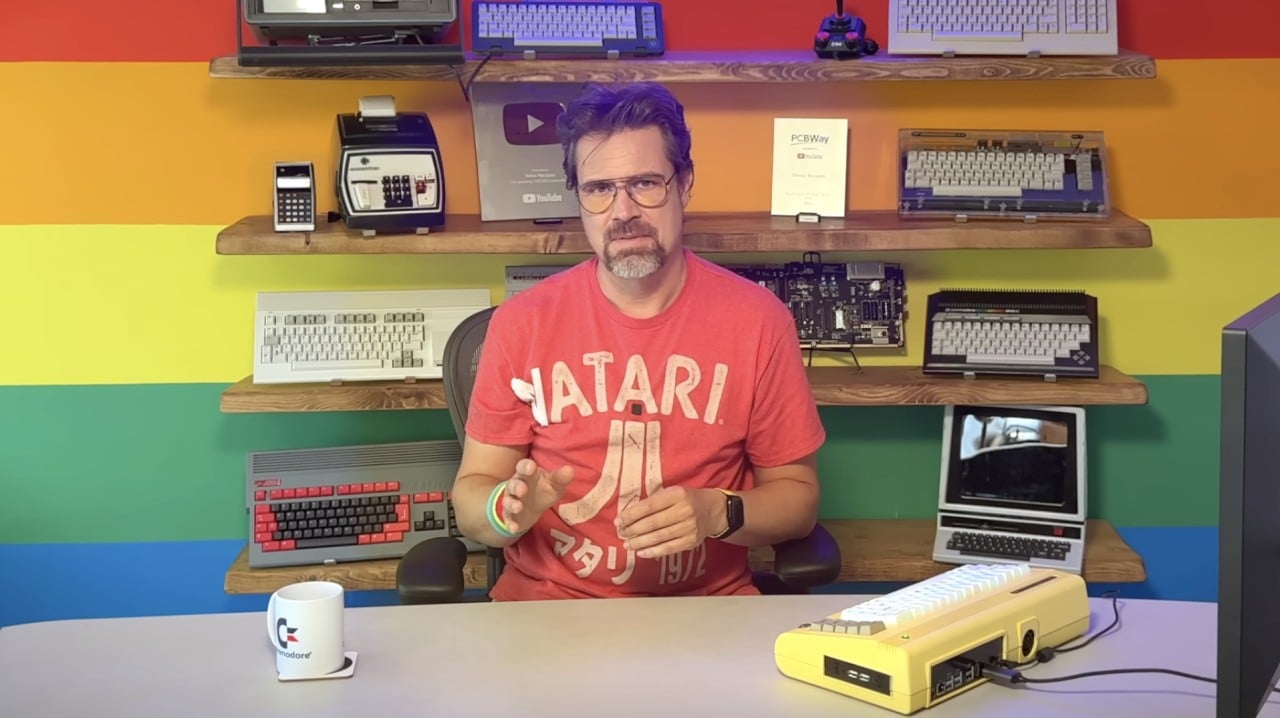

Commodore acquisition finalized

Gmail users urged to change passwords urgently