T4K3.news

Motorola's US smartphone production effort faced challenges

In 2014, Motorola abandoned its US assembly of the Moto X due to high costs and labor shortages.

Motorola's struggle offers insights for today's companies considering US production.

Lessons from Motorola's Attempt to Build Smartphones in the US

In 2013, Motorola sought to gain market share in a smartphone landscape controlled by Apple and Samsung by assembling its Moto X in the US. Dennis Woodside, then CEO, noted American consumers showed interest in domestically produced products. However, despite an innovative approach allowing phone customization, the initiative failed. By 2014, production had shifted back overseas due to high costs and challenges in finding skilled labor. As tariffs loom over imports from Asia, Woodside stresses that companies must be prepared for workforce challenges if they aim to produce smartphones in America.

Key Takeaways

"You have to have a very strong value proposition to the employee."

This highlights the need for companies to attract and retain skilled workers.

"There definitely were higher costs, which was challenging."

Woodside reflects on the economic difficulties faced during Motorola's production attempt.

"We had to train people on that specific type of work."

Emphasizes the training challenges Motorola encountered with its workforce.

"Understanding the nature of the product... is crucial for workforce planning."

Woodside warns against underestimating the skills required for manufacturing jobs.

Motorola's brief attempt to produce smartphones in the US illustrates the broader issues surrounding American manufacturing today. With increasing pressures for domestic production, companies are reminded of the systemic challenges in skilled labor and operational costs. As the industry evolves, firms need to adapt by emphasizing employee value and integrating advanced automation to stay competitive. The landscape is shifting, but sustainable domestic manufacturing hinges on addressing the foundational workforce shortages that persist in the tech sector.

Highlights

- Manufacturing in the US requires skilled workers who are hard to find.

- Companies must think deeply about their employee value proposition.

- Motorola's experience shows the complexities of US production.

- Attracting talent for factory jobs is a steep challenge.

Challenges in US smartphone manufacturing loom large

Motorola's struggles showcase the significant barriers to ramping up domestic production, highlighting workforce shortages and high costs. This situation may provoke public reaction regarding manufacturing policies and job creation.

As the technology sector navigates these challenges, the lessons from Motorola's past could shape its future.

Enjoyed this? Let your friends know!

Related News

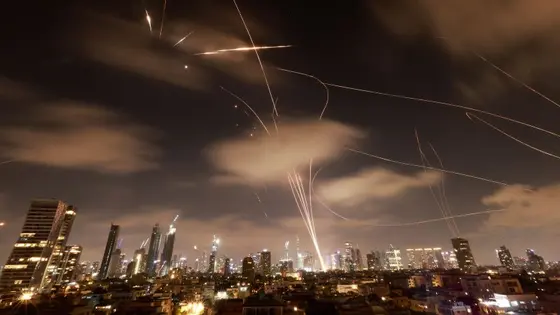

Israel faces new pressures

US and allies struggle with missile defense

At Home announces closures in bankruptcy restructuring

New insights on the challenges of generative AI

Trump signals peace talks with Russia ahead of Alaska summit

Users bet on topics for Apple's earnings call

Canon restarts production of G7 X Mark III

Factory staffing under policy pressure