T4K3.news

Ford doubles down on US EV push

Ford announces a $2 billion retooling of Louisville for affordable EVs set to launch in 2027, featuring a three branch production system and a CATL battery platform.

Ford commits $2 billion to retool the Louisville plant for a low-cost EV pickup launching in 2027 using a three-branch production system.

Ford bets big on new production system at Louisville plant to cut costs for affordable EVs

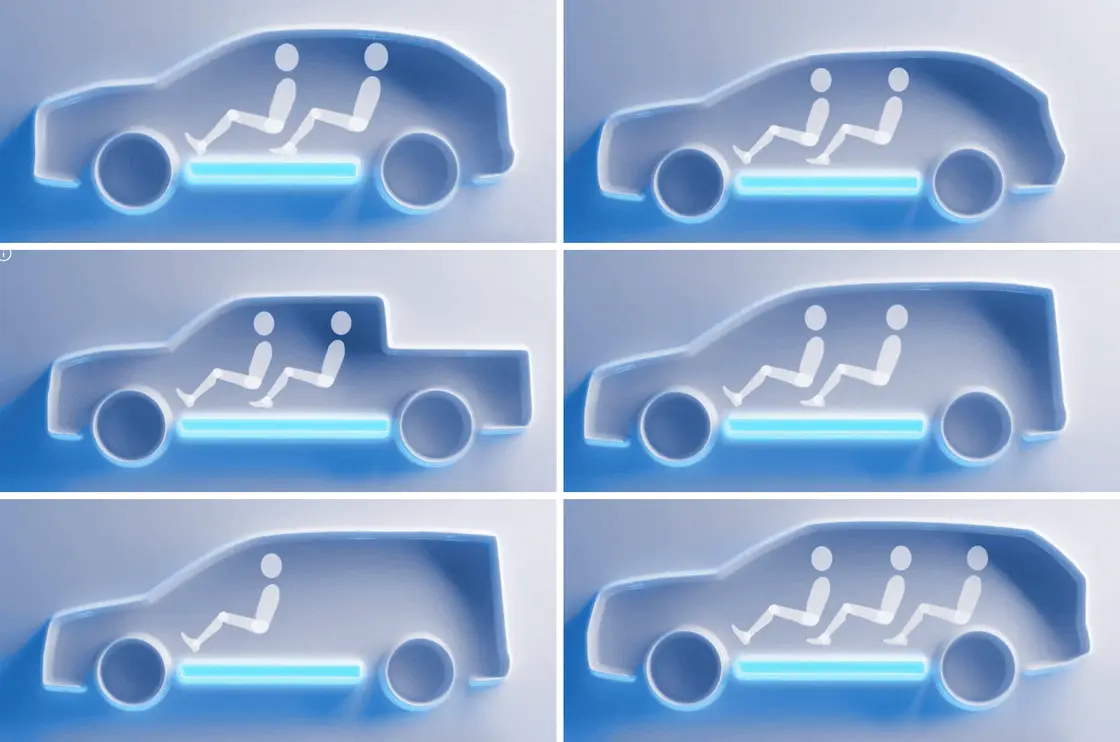

Ford said it will invest $2 billion to transform the Louisville Assembly Plant into a hub for a new generation of affordable electric vehicles. The centerpiece is a universal production system that replaces the traditional single conveyor with a three-branch assembly tree and a shared EV platform. Ford plans a mid sized pickup with a base price near $30,000, targeting a 2027 launch and using lithium iron phosphate batteries licensed from CATL, produced at a separate $3 billion battery plant in Michigan. The company says the change will cut parts and speed up building, boosting output by about 15 percent. The Michigan battery site is expected online in 2026 and will employ about 1,700 hourly workers.

Louisville will stop producing the Escape and Corsair as it switches to the new EV family; production of the current models will continue through the end of the year. When fully running, the plant will support roughly 2,200 hourly workers, about 600 fewer than today, with some staff offered roles at other facilities or a retirement package. Ford says it has secured buy in from the United Auto Workers, with officials praising ergonomics and safety gains. The company describes the project as a bet with no guaranteed outcome, acknowledging risk while arguing it is necessary to stay competitive in a cost sensitive market.

Key Takeaways

"There are no guarantees with this project"

Farley on the risks and the nature of the bet

"I’ve certainly never seen anything in the public domain that looks anything like this"

Clarke on the novelty of the production system

"Ergonomics has been taken into it a whole lot more"

UAW representative on safety and worker welfare

"This isn’t really, you know, optional"

Clarke on the necessity of the transition

The move signals a shift from labor intensive carmaking to modular, kit based assembly. If the three branch system and the shared platform deliver the promised speed and cost cuts, Ford could gain a foothold in the growing US EV market and set a template for others. The plan also leans on CATL licensed tech and a large scale battery plant, tying U.S. production to a global supply chain and adding a layer of strategic risk. Still, the spares light on parts and faster assembly could transform factory economics if the execution holds.

Highlights

- There are no guarantees with this project

- We are doing many new things and I can’t assure this will go just right

- This isn’t really optional

- Ergonomics has been taken into it a whole lot more

Job cuts and automation at Louisville EV shift

The switch to a three branch assembly system will reduce hourly workers by about 600 at Louisville, boosting automation and changing roles. The project carries high capital costs and relies on a new production method, inviting scrutiny from workers, investors, and policymakers about jobs, margins, and supply chain resilience.

The test will be how quickly Ford can translate design gains into steady profit and steady jobs.

Enjoyed this? Let your friends know!

Related News

Ford announces affordable EV rollout

Ford expands EV push with Kentucky overhaul

Automaker bets $2 billion on Louisville EV plant

Ford rolls out cheaper EV pickup plan

Automakers react to Trump EV policy shift

Tariffs and Chips Plan Threaten Auto Makers

Ford bets on a 30k EV pickup

Trump's trade war winds up as a consumer headache